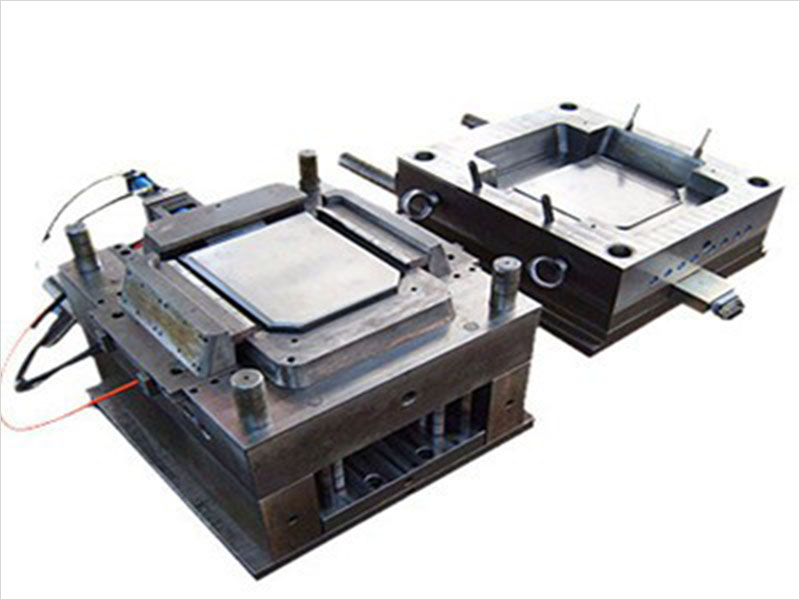

Now the trend of society, the development of mold is very rapid. Plastic mold injection processing is deeply loved by people. Under the market prospect, the future can be expected. Shandong Zheng's Plastic Mould Factory conforms to the development of the times, and its technology is improving rapidly.

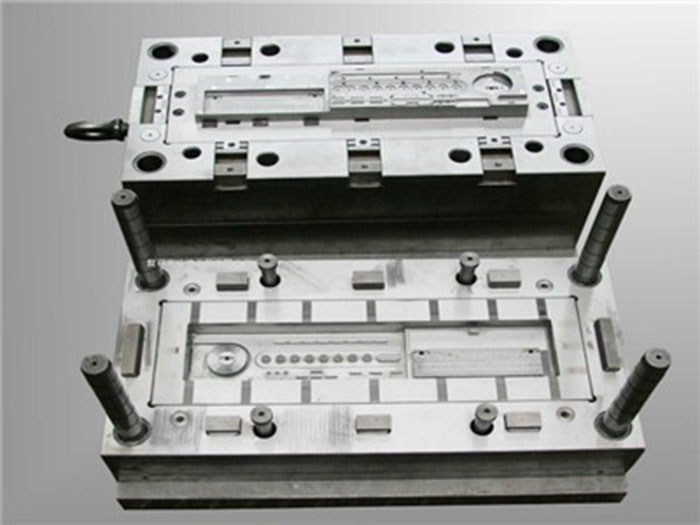

The present situation of the development of injection mold the present situation of product structure China's plastic mold industry has experienced more than half a century, and has made great progress. In the large mold, we have produced 48 Inch large screen color plastic shell injection mold, 6.5kg large capacity washing machine, complete plastic mold, as well as car bumper and integral dashboard plastic mold. In terms of precision plastic molds, we have been able to produce plastic parts and molds for cameras. Cavity small module gear mold and plastic mold.

At present, the hot runner mold has been gradually popularized, and more than 20% has been used in some factories. They usually use internal heat or external heat hot runner equipment, as well as the world's advanced level of difficult needle valve hot runner equipment. The world's advanced level of needle valve hot runner mold. However, the adoption rate of hot runner is generally less than 10%, which is quite different from that of 50% to 80% abroad.

The application of CAD / CAE / CAM with the rapid development of light industry and automobile manufacturing, mold design has been widely concerned, and formed an industry. However, China's mold industry is lack of technical personnel, variety, low precision, short manufacturing cycle, short life, short supply. Some large, complex and complex molds cannot be manufactured by themselves. It takes millions and tens of millions of dollars to import from abroad every year, which limits the development of the mold industry. Therefore, it is imperative to develop the mold industry. In order to improve the design level and processing ability of mold enterprises. The CAD / CAE / CAM system recommended by China Die & mould association is suitable for Die & Mould Company and national die & mould industry.

The CAD / CAE / CAM system for mold design and machining does not need a very large system, but it needs high requirements in some aspects, such as surface modeling and three-axis CNC machining. Although some foreign CAD / CAE / CAM systems have powerful functions of 3D surface modeling, structural finite element analysis, computer-aided manufacturing and product data management, they are expensive and hard to bear for general companies.

Plastic mold injection processing station in the forefront of the development of the times, in the development trend of the wind, the future can be expected.